Normally i talk about reservoir stimulation and engineering topics, but today i am discussing something very unique - something that I feel personally intrigued about. It is the use and key role of weight gauge in well intervention activities (such as slickline jobs, wireline jobs and even drilling & workover operations).

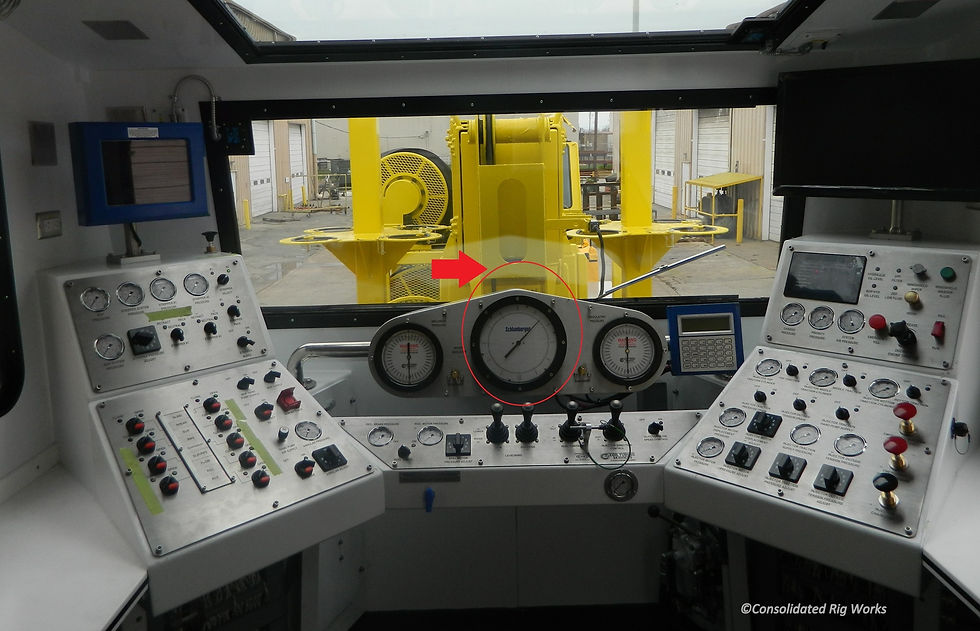

From personal experience, being part of a multidisciplinary subsurface team, I have designed, executed, supervised several jobs that required sending a tool down the wellbore (several thousand feets down) and conducting an activity. Activity may involve running a clearance tool on slickline, replacing a gas-lift valve in side-pocket mandrel, perforating through wireline or setting a production packer through drill-pipe. In all of these jobs (and equipments), the operator has a giant clearly visible ideally located weight indicator in their control cabin, and the entire job execution is focused on the behavior of the single needle on this vitally important gauge.

Basically, when ever a tool is lowered in the well through any wire/e-line or pipe, the only directly measurable property of the system is the weight on the wire or cable. The weight of all tools sent downhole are pre-known, while the weight indicator linearly increases the weight as we send the tool downhole (due to the addition of the weight of wire as keep going down). So basically you have a tool that 10 Kg, you connect to a wire and start sending it down the hole. Your weight indicator that is connected to this wire reads 10Kg initially and keeps increasing linearly as more wire is drawn (because tool lowers down the hole). Now the weight indicator gauge becomes vitally important to the job. the operator uses it to identify the following scenarios:

1. When travelling downhole if weight keeps increasing linearly as we go downhole - then - Everything is ok, tool is travelling down fine and the hole is ok, no obstruction is being detected.

2. When travelling downhole If weight increase starts to slow (increasing slowly now) - then - System is still ok but tool is experience drag or heavier medium which is providing buoyancy (in essence you are loosing the tension of the cable it is slacking)

3. When travelling downhole, if weight drops abruptly, you most likely have a break in the tool assemble somewhere or your tool has hit something and is now sitting on that obstruction or profile (zero tension in the wire now, its completely slacked)

4. When pulling upwards, if weight starts to increase exponentially, the tool is stuck somewhere in the whole and you are over-pulling (increasing the tension in the cable) which will break if over-pulled beyond strength of wire

Weight Indicator on Rig control cabin - reference consolidated rig works

Wireline unit weight indicator - reference Koller-celle

It is amazing how from just one gauge, a simple weight indicator, we deduce a river of information about what is happening thousands of feet down the ground. Quick fact - experienced intervention operators perform tool jobs within 1 ft accuracy by using data from just a weight indicator. Impressive, human beings are brilliant!

These phenomenon are common for all type of interventions, slickline, wireline, coiled tubing, drill pipe etc. In slickline, the weight indicator has even more responsibilities. The ups and downs, small movements tell your information about the tool movement downhole. However I believe slickline and weight indicator needs it own MiLog.

Well i agree that digitization did alot of work for the technician in terms of logging data, however with alot of electronic systems come dependency on the system.. in the old days, a weight indicator was more than enough to give you all the information you require to say, go down a well, and replace a faulty gas lift valve. Ofcourse we cant ignore the depth meter as it is a crucial indicator. Although i have seen slickline jobs where depth meter goes crazy and the weight meter is used to complete the job as per design (assuming that deeper we go the greater the weight).

I like the idea of a force indicator, but wonder how will we measure the acceleration throughout as i bet it wouldnt be constant given changing environment such as moving from gas filled wellbore to fluid.